Production Systems and Manufacturing Technologies for Chassis and Powertrain of Rail Vehicles

The European companies of the FFG Group serve the production companies and maintenance works for chassis and drive of rail vehicles with optimal products and manufacturing technologies. A team of successful specialists with many years of “Rail” industry experience guarantee high quality and the best economy with the most modern manufacturing solutions (machine, technology and peripherals) for the respective component processing.

The systems operate in the area of maximum availability with the appropriate component and process flexibility for the special tasks. The design of complete production systems and delivery of turnkey projects for single and series production by the system supplier and integration partner MAG as well as global service coverage with our own technicians is the key to a high degree of utilization and cost efficiency. In close cooperation with planning, project execution and production support, the operator can use the “Digital Factory” to help shape the successful implementation.

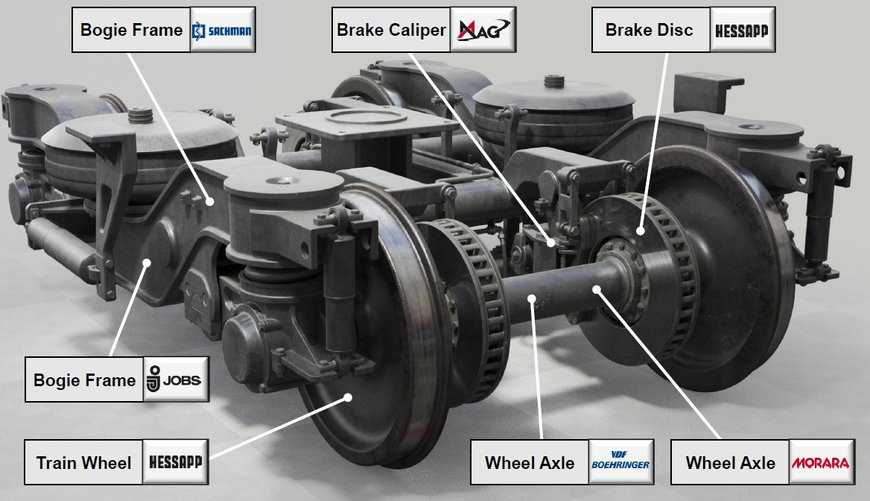

There are two machine concepts available for the size of a chassis frame, both of which have a swivel spindle head. The swivel spindle offers an ideal solution for the structurally restricted access to the machining point. The gantry type milling center EVER5 (X / Y / Z: 9,500 / 4,000 / 1,250 mm) from JOBS (Fig. 4) with two work areas (fixture nests) on the table can be loaded and unloaded alternately, parallel to the main time, without interrupting processing. The traveling column machine THOR (X / Y / Z: 6,000 / 1,200 / 2,000 mm) from SACHMAN is equipped with a KOSMO milling head with a spindle speed of 4,000 rpm. With this solution, workpiece supply can also take place at the same time as the use of a second W- axis feed unit with an integrated B-axis rotary table in shuttle mode. The W-axis enables the workpiece to move towards the tool, particularly in the case of heavy and high-precision machining, and thus avoids a corresponding overhang on the tool side by moving out the Z-axis. Both machines can change the machining heads automatically and change tools via a sufficiently dimensioned tool magazine for complete machining of the bogies.

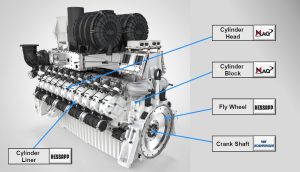

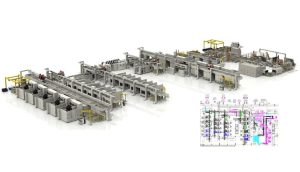

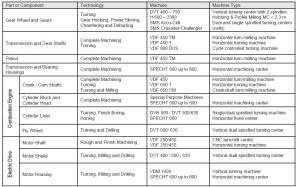

The system competence for planning and execution of the FFG group is represented by the MAG brand. With its own product portfolio of special machines and CNC machines including process and equipment for machining, assembly and measuring stations, system automation (gantry loader or robot) and purchased systems, MAG supplies individual machines and production systems for the series production of housing components, e.g. cylinder blocks, cylinder heads, transmission cases, housings for e-drives, as well as complete turnkey systems for these components, according to the respective customer specification (Figures 5 and 6). An experienced team of project managers is available to coordinate the project and all co-suppliers. For project execution the latest software tools for the Digital Factory will be applied, e.g.: for the process design and optimization of the machining programs the virtual reality simulation is used. Simulation models are already created in the mechatronic design phase, with which virtual commissioning of the products and processes can be started even before the real system is built (Figure 7). In cooperation with the suppliers of special and peripheral machines as well as automation, the commissioning of the functions of a production system can be carried out on a virtual model without erection of the real units in one common location and in higher quality, lower costs and shorter delivery times compared to conventional project management. These models are also available to the customer as a demonstrator for training operators and maintenance personnel. In addition to the digital product twins, the digital process twin for processing sequence and digital system twin, which optimize the system for the desired availability and prove it on the simulation model, are created in the proposal phase.

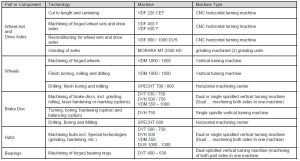

For the vertical machining of disc-shaped components such as railway wheels and brake discs, HESSAPP, with its many years of experience, offers a wide range of process knowledge for all core processes and optional technologies (ceramic components, lasers, hardening, grinding) for several complete series of turning machining centers (Table 1). The VDM series with sizes 550 to 1,600 mm is used for wheels and brake discs. With a maximum turning diameter of 1,600 mm (swinging diameter 1,800 mm), an output of 165 kW and a payload of 2.5 t, wheels with all material specifications (ER 6 to ER9) – regardless of the area of application of the wheels (freight, metro or high speed) – can be rough and finish machined with highest quality on the VDM 1600 machine with a capacity of 48 tool positions (Figure 8). The VDM 1000 machine is an economical counterpart for smaller wheels with a turning diameter of up to 1,150 mm.

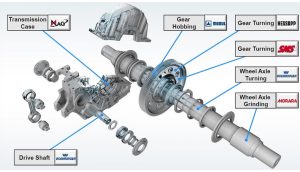

The powerful horizontal CNC lathes of the VDF series from BOEHRINGER are designed for hard machining and highest component quality. With frame sizes VDF 450 and 650, all requirements for the wheelset axles and drive shafts can be covered and the required processes (rough turning, fine turning, milling, gear cutting and other machining with driven tools (drilling, threading, milling)) can be covered (Fig. 10). The machines are built on hydropol beds for maximum mechanical and thermal stability. This achieves maximum vibration damping as the basis for the finest surface quality, extended tool life and thus reduced tool costs. With the process know-how of the BOEHRINGER turning specialists, these robust, durable and high-precision machines produce grinding qualities when required.

Vertical lathes of the brands HESSAPP and SMS are suitable for machining the gearwheels in the powertrain of the driven vehicles. The gear cutting machines from MODUL H 600 to H 2300 are designed for the series production of large gears up to m <28 and workpiece diameters up to 2,400 mm. The machines can be used for all hobbing and form milling processes for soft machining as well as for the finished machining of hardened gears. In addition to spur gears, helical gears, spherical or conical gears can be manufactured using hardware and software options as well as shafts with multiple gears, worm gears and other special profiles. The MODUL H 600 to H 800 series is loaded with the integrated ring loader. The larger machines are linked with classic automation systems (e.g. portal loaders,robots, etc.). In accordance with the high machining forces and stresses involved in the manufacture of gears, the large MODULE H 900 to H 2300 series features box ways with coating.

The machining of vehicle wheelsets for the service is becoming increasingly important. Recent studies [1,3,4] do recommend the machining of the wheels at each service stop (approx. 70,000 km) with a material removal of 1 mm compared to the previous condition-based reworking of the profiles with a material removal of 4 – 5 mm. The elimination of surface defects in the rolling contact area that begin with fatigue crack formation are the new approaches to significantly reduce maintenance costs in connection with a possible doubling of the service life to up to 1.6 million km mileage [2]. In addition to special machines for turning wheelsets in an installed (underfloor lathes) or removed (above-floor gantry machines) condition, CNC lathes such as the BOEHRINGER VDF DUS 800/1000/1110 (turning length 820 to 1,110 mm above bed, Figure 14) up to size VDF 1300/1500/1600 DUS (1,300 to 1,600 mm above bed) are also available for the repair shop for smaller series. A highlight of the series are the hardened double prism guides with scraped guide surfaces on the slide, which are the basis for the high and durable machining accuracy and highly economical production.